Research

Our products and services are the result of continuing research and development efforts for many years. And, we are serving rapid solutions for industrial requirements having long term research activities.

Our research approach can be summarized as; initiative, inovative, solution oriented, responsible in the projects, agressive and proactive.

Our research activities;

- 1. Up to date industry and technology follow up

- 2. Customer projects

- 3. Research and development cooperations

- 4. In house strategical projects

Know How and Experience (Technology)

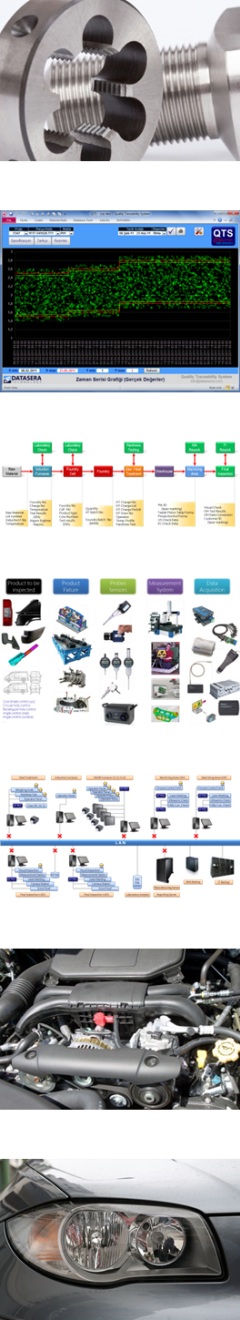

- Data acquisition, remote data acquisition

- Machine automation and control

- Machine – equipment – software Integration

- Automation, PLC, SCADA, DSC, OPC servers

- Traceability, telemetry

- Data mining – data storage – data processing

- Neural networks and special algorithms

- Mathematical Modeling and Simulation

- Database design and architecture

- Industrial barcode and RFID applications

Manufacturing Systems Experience

- Manufacturing Execution Systems (MES)

- Material Requirements Planning (MRP)

- Master Production Scheduling (MPS)

- Manufacturing ERP, WIP Inventory

- Quality Control, Process Control, SPC

- Material Analysis

- Engineering Management

- Kanban, Lean Manufacturing

- KPI Systems, Efficiency Monitoring

- EDI Systems

Special Algorithms and Data Architectures

The projects which are dependent on advanced algorithms and data architectures are in our focus. We have several real life advanced projects

Example-1 (Manufacturing Optimization): The decissions are applied in a manufacturing plant with an accuracy of >95%, where >1 x 10500 huge amount of conditions exist. Without this system, the manufacturing operations are excuted with 50% accurate decissions, +35% machine, and +40% workforce.

It is almost impossible to overcome this amount of operational/mathematical problem with normal techniques and with normal computers, infact with grid technology. In addition, this problem constitutes in every shift (8 hours). With neural network (learning, self-developing, human brain methodology) techniques, this industrial problem solvable in 3 minutes with normal computers. The development of algorithm takes about 2-5 months with itself.

Example-2 (Manufacturing Traceability System): Yearly ~1.500.000 number of products are produced with the machines, which are generates too many gigabites of data. These data should be traced easily for several years in realtime. There are many similar but different issues in the industry. This project has overcomed with special data collection and storage architecture with in 3-4 weeks.